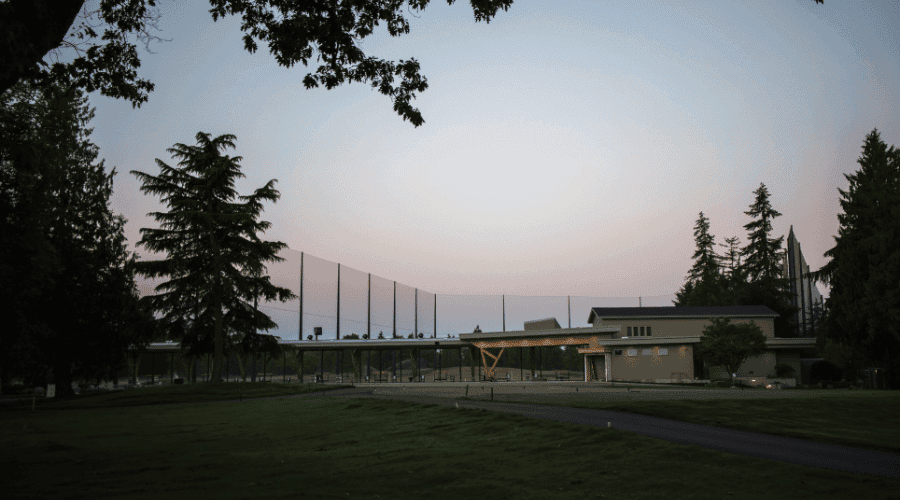

Point Grey Golf Course Project: How Infrastructure Engineering Drove ROI & Safety

When a prestigious facility like Point Grey Golf & Country Club undergoes a major renovation, the architectural design often takes centre stage. But for facility operators and owners, the real success story lies behind the scenes, in the engineering that keeps the range operational, safe, and profitable.

At Netex, we know that complex projects require more than just a standard catalogue solution. For Point Grey, the challenge was to deliver massive vertical netting without compromising the aesthetic of a high-end urban course. This case study breaks down how we utilized custom steel engineering and integrated technology to solve strict space constraints and turn a standard safety expense into a long-term revenue generator.

Project Specs at a Glance:

- Location: Vancouver, BC (Coastal Wind Zone)

- Height: 115’ Custom Engineered Steel Poles

- Material: Dyneema #6 (Low-Vis, High-Tenacity)

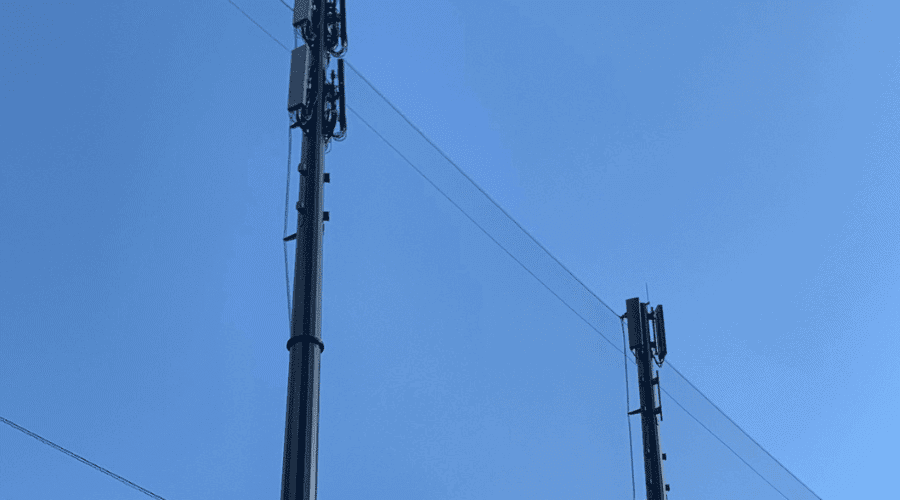

- Innovation: First Telecom-Integrated Driving Range Pole

- Certifications: CWB Certified Welding, P.Eng Stamped Drawings

Key Takeaways:

- Revenue Generation: How Netex developed the industry’s first telecommunications-ready driving range pole to generate income from cellular providers.

- Space Optimization: The use of precambered steel poles to eliminate guy wires, allowing for extended fairways and greens.

- Structural Safety: The installation of 115-foot custom poles supported by engineered pile foundations to withstand coastal wind loads.

- Operational Efficiency: Full integration of G2 1000w LED lighting and Dyneema #6 netting for maximum durability and visibility.

Gaining Ground: The “Guy Wire” Problem

Space is usually the biggest headache in any facility upgrade. You want maximum netting for safety, but you don’t want to sacrifice playable turf to get it.

At Point Grey, we ran into a classic problem. Traditional netting systems often rely on guy wires, those heavy cables anchoring the poles to the ground, to keep them standing straight. The problem? Guy wires eat up real estate. They create “dead zones” around the perimeter that you can’t use for play.

We knew there had to be a better way to use the land.

The Fix: Pre-cambered Steel Poles

Instead of standard poles, we engineered a solution using pre-cambered steel poles. If you aren’t familiar with the term, think of it like an archer’s bow. We manufacture the pole with a slight, calculated curve against the load. Once the heavy netting is installed, that tension pulls the pole perfectly straight.

By baking structural strength directly into the steel’s curve, we removed the clutter of cables, leaving a clean, self-supporting barrier that doesn’t consume a single foot of your playable land.

The result was immediate. Without those cables cluttering the perimeter, Point Grey was able to extend its greens and fairways, reclaiming valuable yardage that would otherwise have been lost to infrastructure.

Vertical Reliability: 115 Feet of Netting

To protect the surrounding neighbourhood and the new facility, a standard height wouldn’t suffice. We installed a full range of 115-foot-tall custom-engineered steel poles to ensure total ball netting. This aligns with our commitment to providing custom-built solutions for multi-sport facilities.

But when you build that high in a coastal climate, what’s underground matters just as much as what’s in the air.

Think of these foundations like an iceberg. You might see 115 feet of steel in the air, but the massive engineered pile foundations underground are doing 90% of the work against the coastal winds. We drilled deep to ensure those towers stay stable, regardless of the weather. This hands-on management from design through to installation is central to our precision approach.

For the netting itself, we utilised Dyneema #6 netting. We chose this specific material because it offers the “Holy Grail” for golf ranges: incredibly high strength with a very low visual profile. It practically disappears against the skyline while delivering maximum durability, addressing liability risks from damaged or unsafe netting.

Turning Infrastructure into Income

Here is where the project gets really interesting for anyone managing a budget. Usually, a steel pole is just a cost. It sits there, holds a net, and depreciates.

We wanted to change that math.

At Point Grey, Netex developed the first telecommunications driving range pole in the industry. We designed the structure to double as a cell tower, seamlessly integrating the equipment without compromising the netting or aesthetics.

Now, instead of just being a safety expense, that infrastructure enables the course to generate ongoing income through leases with mobile carriers. It’s a safety barrier that pays for itself.

Lighting the Way

Finally, to ensure the facility could operate efficiently well into the evening, we supplied G2 1000w LED lights for the whole range.

How much money are you burning while waiting for old halogens to warm up? We swapped the old standard for instant-on G2 1000w LEDs. These units provide instant, crisp visibility, enhancing the player experience and reducing long-term energy costs, directly addressing the challenge of poor or outdated lighting systems.

The Netex Difference

The Point Grey project proves the value of a turnkey partner. We didn’t just supply parts; we handled:

- Engineering: Custom precambered design to maximize playability.

- Civil Works: Pile foundation drilling and setting.

- Installation: High-altitude netting and lighting deployment.

- ROI Strategy: Telecom integration planning.

From extending fairways with intelligent steel design to generating revenue with telecom integration, this project proves that infrastructure upgrades can do more than just “fix” a problem, they can improve your business model. This level of coordination eliminates the headaches of multiple trades involved in one project.

Conclusion

The Point Grey project demonstrates that a netting system can be more than just a safety requirement; it can be a strategic asset that saves space and drives revenue. By choosing a partner capable of handling the entire lifecycle, from foundation engineering to lighting supply and installation, facilities can eliminate the coordination headaches of managing multiple trades.

Whether you are dealing with tight property lines, strict aesthetic requirements, or the need to modernize aging infrastructure, the “Point Grey approach” proves that precision engineering delivers the best ROI.

Next Steps: Are you planning a facility upgrade that requires custom engineering or space optimization? Contact the Netex design team today to evaluate your site’s specific needs and discover how our turnkey solutions can maximize your facility’s potential.

About the Author: Mark Wilson is the founder of Netex Netting (Netex Canada Netting Inc.), a global leader in golf and baseball netting systems. With 47+ years of net-building expertise, he pioneered low-drag Dyneema® golf nets and designed integrated pole, lighting, and turf solutions. Netex delivers precision installations worldwide and stands behind them with industry-leading warranties.