Netex Engineered Sport Netting Systems

Netex offers a complete engineered solution for your sports facility

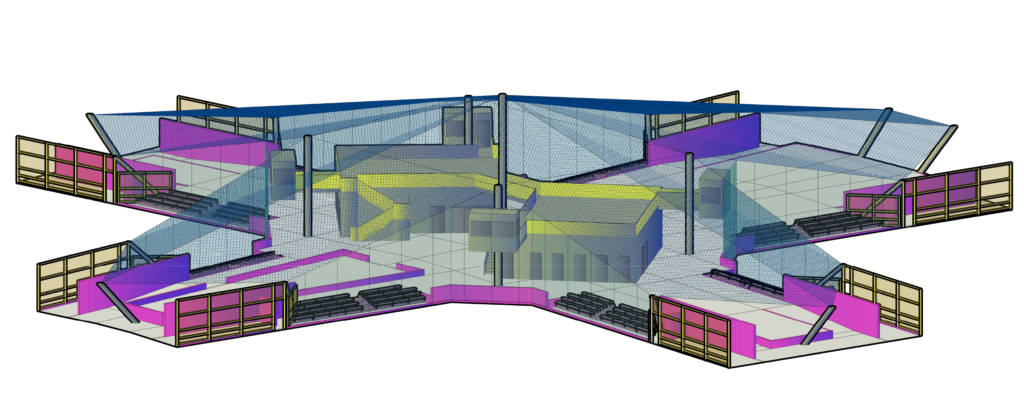

Netex offers its clients a total sports netting solution with engineering design, supply, and installation services. Our in-house design service means that we are in complete control of the quality and design of your project from start to finish. We pay attention to every detail during the design process, to produce clean-looking net support structures that are stronger, more durable, cost less to install, and require less maintenance than other systems on the market.

“We specify Netex on all of our athletic complex designs with unique design challenges, with full confidence that the project will be successful.”

Bruce Dees, FASLA

Bruce Dees & Associates

Tapered steel poles offer a clean look and efficient design

Netex advanced sport netting systems use engineered, tapered steel poles for net support. Tapered poles provide design efficiency by putting the strength where it is needed, at the base of the pole.

Freestanding engineered steel poles eliminate the maintenance and spectator-hazard issues of guyed systems.

Pole taper and steel thickness are selected to match the applied loading all the way up the pole, to optimize steel usage and pole weight. Our end, corner, and angle poles can be designed as freestanding and precambered for a clean look, with none of the maintenance or spectator-hazard issues associated with guyed systems. We can also supply conventional, pressure-treated wood poles in sizes up to 140 feet (42.6m).

Pole installation is fast and easy

Our poles are built in sections up to 39 feet (12m) and 44 feet (13.4m) for 40- and 45-foot container transport. Installation is fast and easy, with slip-fit connections that eliminate the need for bolted flanges. Poles can be bolted to steel or concrete foundations, or direct-buried.

Wind tunnel test results help us design safer structures

As Yogi Berra famously stated, “In theory, there is no difference between theory and practice. In practice there is.” After more than 20 years in the sport netting industry, we knew there could be a measurable difference between theory and practice when it came to wind drag on sports netting. That’s why we decided to invest in wind tunnel testing for our netting.

Our test results show that the actual wind drag on many nets typically used in the industry is much higher than assumed.

When we measured the wind drag of our Dyneema® netting versus polyester netting, the results surprised us. The industry’s “theoretical assumption” for wind drag on a typical polyester or nylon golf barrier net was a drag coefficient of 8%. Our test results showed, however, that the actual wind drag on some of these nets was in the 12 to 16% range… 50 to 100% higher than the wind drag figures typically being used to determine wind load for the design of support structures!

In the interest of public safety, Netex shared the wind tunnel test results with anyone in the industry who would listen – but not everyone has.

Netex Dyneema netting has the lowest wind drag of any net on the market

The wind tunnel test results for our #6 Dyneema golf barrier net, with a twine diameter of 0.8mm (versus a typical polyester twine diameter of 1.1 to 1.3mm), came in at 9.4% drag – 40 to 50% lower than conventional netting!

We’ve innovated with wider spans and taller barriers

Netex nets fabricated from low-drag, lightweight, high-strength Dyneema fibre allow us to innovate and design with wider spans and taller structures. We offer the widest spans in the industry – up to 82 feet (25m) in standard designs, and up to 115 feet (35m) in custom designs. Our support poles stretch up to 200 feet (61m) high!

We offer the widest spans between poles in the industry – for a clean look and lower install costs.

One of the advantages of wider spans is that they can reduce your installation costs. For example, a typical golf driving range is roughly 800 feet (244m) long, with 17 poles on each side and a span of 50 feet (15m) between poles. With Netex’s #6 Dyneema golf barrier net, we can space poles every 80 to 82 feet (24 to 25m) and install just 11 poles per side in the same layout.

Not only are the installation costs lower, there are fewer poles and hardware to interfere with the netting and cause maintenance issues. The difference in the overall “wide open” look and feel of a Netex Dyneema installation versus a conventional polyester net installation is breathtaking.

Netex offers the most low-maintenance sport netting system on the market

By using fewer poles in our design, we also reduce the number of wear points on the netting, reducing your maintenance costs. Over the years, we’ve fine-tuned our installation methods to develop the most low-maintenance system on the market.

No detail is overlooked and no shortcuts are taken – from hand-tying our netting to the perimeter rope, to the abrasive-resistant Dyneema fibre and customized attachment hardware we use, the result is a superior installation that will stand the test of time.

We can integrate LED lighting into your sport netting design

We can engineer our tapered, steel poles to integrate LED stadium lights into your netting application, eliminating the need for additional lighting poles in your sports complex. Our poles can also be used to mount any security cameras, banners, or flags that your facility requires.

Our poles can be engineered to support cell antennas

Netex poles can be designed to support cell antenna installations and provide additional revenue for your facility.

Netex pole warranty

Our poles come with a conditional 2-year warranty. Installations are backed by a 2-year workmanship warranty.

You’ll find the features and specifications for our engineered steel support poles in the PDF below. Please contact us if you have any questions, or to get a quote.